For Thailand Client

Our customer buys this new pump for replacing their old machine.

After discussion, we suggest them this model YSHX-30150 high pressure water blaster pump. It is simple structure, easy to maintenance, stable quality , save cost.

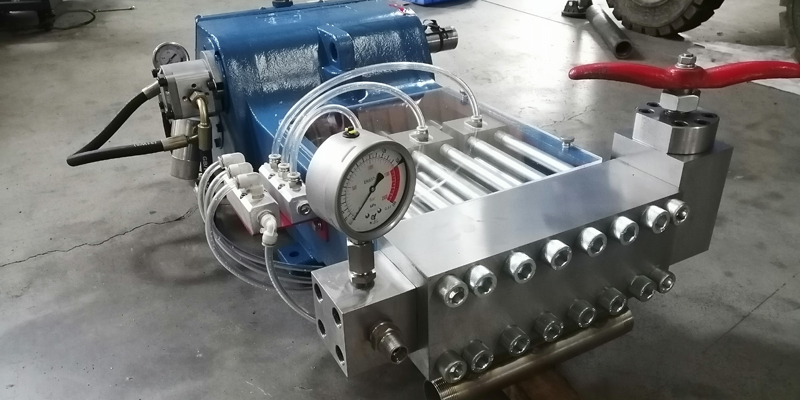

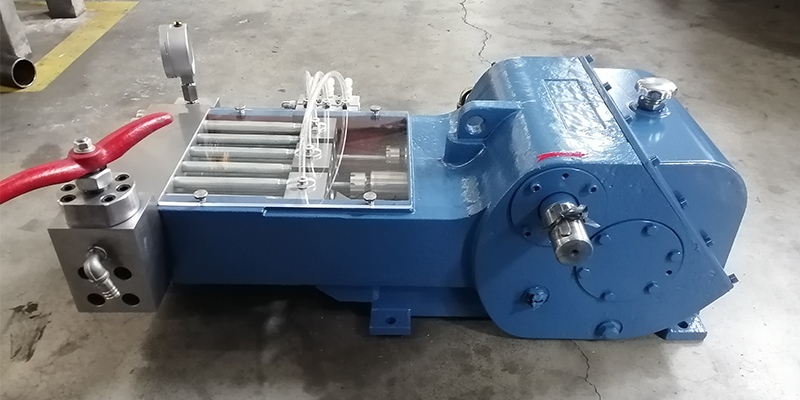

High Pressure Pump

Model: YSHX-30150

Pressure: 800Bar

Water flow rate: 25L/min

Pump plunger material: Cemented carbide (Tungsten carbide)

Pump Speed: 1480min-1

Size: 990*550*450mm

Weight: 300kg

High pressure water blaster pump introduction:

The operating pressure of high-pressure plunger pumps should generally be between 10MPa and 300MPa/40000psi/3000bar. It is a positive displacement pump, which achieves the purpose of transporting liquid by means of periodic changes in the volume of the working chamber; the mechanical energy of the prime mover is directly converted into the pressure energy of the transported liquid through the pump; the capacity of the pump only depends on the change value of the working chamber volume and its The number of changes per unit time is theoretically independent of the discharge pressure. The reciprocating pump relies on the reciprocating motion of the piston in the working chamber of the liquid cylinder (or the periodic elastic deformation of flexible components such as diaphragms and bellows in the working chamber) to cause periodic changes in the volume of the working chamber. Structurally, the working chamber of the reciprocating pump is separated from the outside world by a sealing device, and communicates or is closed with the pipeline through the pump valve (suction valve and discharge valve).

High pressure water blaster pump features

1. The instantaneous flow rate is pulsating

This is because in the plunger pump, the suction and discharge processes of the liquid medium are carried out alternately, and the speed of the piston is constantly changing during the displacement process. In a high pressure water blaster pump with only one working chamber, the instantaneous flow rate of the pump not only changes with time, but is also discontinuous. As the number of working chambers increases, the pulsation amplitude of the instantaneous flow becomes smaller and smaller, and can even be considered as turbulent flow in practice.

2. The average flow rate is constant

Theoretically, the flow rate of the pump only depends on the main structural parameters of the pump n (number of reciprocations per minute), S (piston stroke), D (piston diameter), Z (number of pistons), and has nothing to do with the discharge pressure and has nothing to do with the transport medium.

Physical and chemical properties such as temperature and viscosity are irrelevant. Therefore, the flow rate of the pump is constant.

3. The pressure of the high-pressure water blaster pump depends on the pipeline characteristics

The discharge pressure of a high-pressure plunger pump cannot be limited by the pump itself, but depends on the pipeline characteristics of the pump device and has nothing to do with the flow rate. That is to say, if the transported liquid is considered to be incompressible, then in theory it can be considered that the discharge pressure of the reciprocating pump will not be subject to any restrictions, and any required discharge pressure of the high-pressure pump can be established according to the pipeline characteristics of the pump device. . Of course, all reciprocating pumps have a pump discharge pressure regulation. This does not mean that the discharge pressure of the pump will not increase anymore, but it just means that due to the limitations of the rated power of the prime mover and the structural strength of the pump itself, it is not allowed to Only used when the discharge pressure exceeds this.

4. Strong adaptability to the conveying medium

In principle, the plunger pump can transport any medium and is almost not limited by the physical and chemical properties of the medium. Of course, due to the limitations of the material and manufacturing process of the liquid end as well as the sealing technology, sometimes situations that cannot be adapted will be encountered.

5. Has good self-priming performance

The high-pressure plunger pump not only has good suction performance, but also has good self-priming performance. Therefore, for most reciprocating pumps, there is usually no need to prime the pump before starting. The machine is highly efficient and energy-saving.

Flow rate of high pressure plunger pump

Theoretical flow rate of high-pressure pump: Qt=AsnZ

In the formula, Qt is the theoretical flow rate of the pump; A is the cross-sectional area of the plunger (or piston); S is the stroke; n is the crankshaft speed (or the number of reciprocations of the plunger per minute); Z is the number of couplings (the number of plungers or pistons)

The actual flow rate of the high-pressure pump: Q=Qt-Q.

In the formula, the flow rate of Q pump; the theoretical flow rate of Qt pump; the flow loss of Q pump. The factors causing the flow loss of the pump include: volume loss due to liquid compression or expansion; volume loss due to the lag of the valve closing; volume loss caused by leakage through the sealing surface due to loose valve closing; through the plunger. , volume loss caused by leakage of piston rod or piston ring.

High pressure water blaster pump power

Effective power of high-pressure pump: The energy obtained by the liquid discharged by the high-pressure pump from the pump per unit time is called effective power.

Ne=PQ where Ne effective power, P full pressure, Q flow. After substituting the units, the formula becomes: Ne(KW)=1/36.7×P(Kgf/cm2)×Q(m3/h). Taking into account the power loss caused by the efficiency of the transmission device, mechanical friction, volumetric efficiency, medium temperature rise and other reasons, when selecting the power of the prime mover, for low-pressure reciprocating pumps, N=1/(0.85~0.9)N; for high-pressure reciprocating pumps, N=1/(0.75~0.85)N. Application scope of reciprocating pumps Piston pumps are mainly suitable for high-pressure and small flow situations where the flow rate of the pump is required to be constant or quantitative, to transport various media in proportion, or where good suction performance or self-priming performance is required. In today’s world of energy shortage, reciprocating pumps, as energy-saving products, are widely used in many industries such as energy mining, petroleum fine chemicals, food and drug processing, etc. This type of pump has a relatively complex structure, strong compatibility but poor versatility, many varieties and small batches.