Diesel Pumping Systems, High Pressure Water Jetting Equipment

Export to Brazil

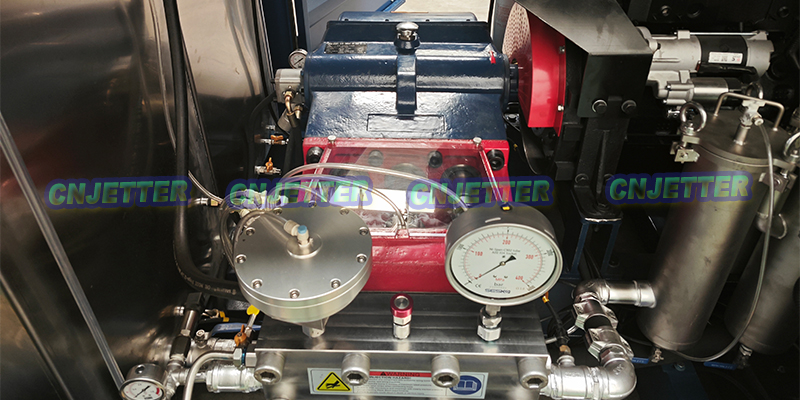

High Pressure Water Jetting Equipment 40,000 psi , diesel engine driven, for our regular client. They have own shipyard, building and repair ships, boats.

CNJETTER High Pressure Water Jetting Equipment in Ship Industry for Paint Stripping and Rust Removal is more and more popular.

The maritime industry is one of the most vital sectors that require regular maintenance and cleaning due to the harsh environment it operates in. Saltwater, sunlight, and operational stress can cause paint to peel and rust to form on the surfaces of ships. 40,000 psi High Pressure Water Jetting Equipment have emerged as a game-changer in the industry, providing an efficient and eco-friendly solution for paint stripping and rust removal. Below, we explore the various uses of high-pressure washers in the ship industry.

1. Enhanced Cleaning Efficiency

High-pressure washers use a stream of highly pressurized water to blast away paint and rust. This method is far more efficient than traditional cleaning techniques such as manual scraping or sandblasting, which can be time-consuming and labor-intensive. The powerful jet of water can quickly remove layers of paint and rust without causing damage to the underlying surface. so, CNJETTER High Pressure Water Jetting Equipment is more and more popular.

2 Surface Preparation for Repainting

Before a ship can be repainted, the old paint and rust must be completely removed to ensure proper adhesion of the new coating. High Pressure Water Jetting Equipment provide a thorough cleaning that creates an ideal surface for repainting. The removal of contaminants and loose paint ensures a smooth and durable finish.

3. Environmentally Friendly Solution of CNJETTER High Pressure Water Jetting Equipment

Compared to sandblasting and chemical stripping, high-pressure washing is an environmentally friendly option. It does not produce harmful dust or require toxic chemicals, thus minimizing the environmental impact. Moreover, the waste water produced during the cleaning process can be captured and treated, further reducing pollution.

4. Versatility and Accessibility

High Pressure Water Jetting Equipment can be used on various parts of a ship, including the hull, deck, and superstructure. They are particularly useful for reaching areas that are difficult to access with traditional cleaning methods. The versatility of these machines allows for the effective removal of paint and rust from both flat and curved surfaces.

5. Reduced Maintenance Costs

Regular use of CNJETTER High Pressure Water Jetting Equipment for paint stripping and rust removal can significantly reduce maintenance costs in the long run. By preventing the buildup of rust and peeling paint, ships can avoid more extensive damage that would require costly repairs. The investment in high-pressure washing technology can lead to substantial savings over time.

6. Safety for Operators

High Pressure Water Jetting Equipment CNJETTER are designed with safety in mind. Operators can perform cleaning tasks from a distance, reducing the risk of accidents and injuries. Additionally, the use of high-pressure water jetting minimizes the need for physical contact with the surface, further enhancing operator safety.