High-pressure water jetting stripe removal machine

CNJETTER specializes in the production of advanced high-pressure water jetting systems designed to efficiently remove stripes from surfaces, catering to both minor and extensive projects. The conventional methods of stripe removal can yield inconsistent outcomes and may inadvertently harm the underlying concrete or asphalt layers. Our water jetting technology offers a secure, rapid, and comprehensive solution for eliminating paint or rubber markings without causing any damage to the surface. Post-removal, the pavement is primed and ready for the application of fresh striping.

Utilizing our high-pressure water jetting systems for stripe removal eliminates the need for abrasive chemicals, enhancing the overall safety of the operation and safeguarding the environment in the vicinity of the removal zone. Additionally, water recovery systems can be deployed to efficiently collect and dispose of the contaminated water produced during the process.

CNJETTER water jetting stripe removal systems are versatile and suitable for a wide range of applications, including but not limited to:

– Parking facilities

– High-traffic roadways

– Airfield runways

– Bicycle lanes

– Residential driveways

– And numerous other surfaces requiring precise and non-destructive stripe removal.

Configuration advantages and features of CNJETTER water jetting stripe removal machine:

- Simple loading method: It can be directly loaded on the trucks that meet the main engine size requirements owned or purchased by the customer without the need for a special vehicle chassis, which can improve the user’s vehicle utilization efficiency and effectively reduce the capital investment in construction vehicles.

- Strong operational reliability of CNJETTER water jetting stripe removal machine: The entire system adopts a large-flow 250MPa ultra-high-pressure water pump. The key components such as the engine, ultra-high-pressure water pipe, and hydraulic rotary joint are all made of high-quality materials. One maintenance can last for 500 hours, providing operational reliability for the equipment.

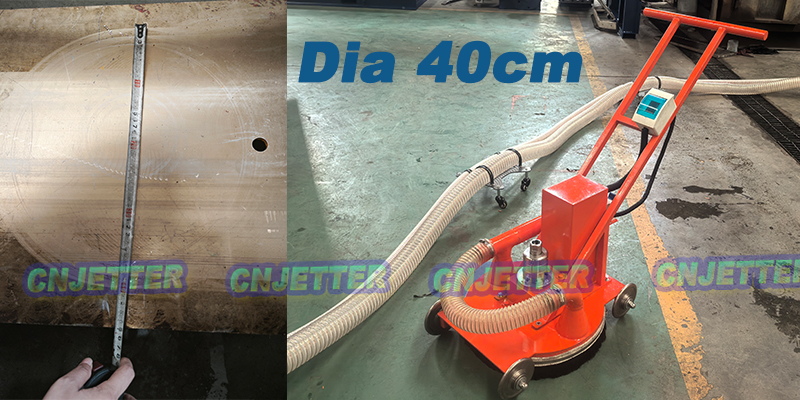

- Flexible cleaning device: The hand-push cleaning operation end is easy to operate and more flexible to use. It can adapt to the marking cleaning operation under various working conditions. CNJETTER water jetting stripe removal is always the good choice.

- System safety protection function: Use 1-5μm fine filtration, configure automatic prompt replacement when the filter element is blocked, automatic shutdown when the pressure is too high, automatic alarm and shutdown when the filter pressure difference reaches the set value, etc. System self-protection functions provide strong guarantee for the safe operation of CNJETTER water jetting stripe removal machine.

- Thorough recovery: Equipped with a patented slag water recovery device to ensure that there is no dust, residue and sewage at the construction site. The slag discharge port is hydraulically opened and closed, with an inner bevel design and an oversized material door to ensure smooth slag discharge and convenient and quick unloading, which can significantly save time and manpower.

- Unique anti-corrosion and anti-rust performance for CNJETTER water jetting stripe removal machine.

Export to Spain

After visiting our factory, the Spanish customer decided to purchase one road marking stripl removal machine as a trial order. If the machine works well in the local construction, they will order another 5 sets strip removal machine. Welcome all customers who need this machine to contact us. We will reply and quote you within 8 hours.

Customize the trolley size, expand to 400mm removal diameter.