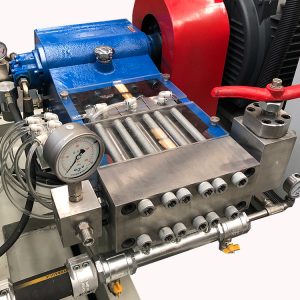

30150 Pump

YSHX30150 ultra high pressure pump adopts American advanced high-pressure technology, with compact overall structure, small size, light weight, high work efficiency, etc., easy to maintain and operate, and low noise. Water flow rate < 30L/min, Max Pressure 1500Bar.

Most advantaged feature is Cemented carbide, tungsten carbide plunger.

Power end introduction of ultra high pressure pump :

The prime mover drives the high-speed shaft to transmit torque to the crankshaft through a pair of herringbone gears, while reducing the speed. The crankshaft converts the rotary motion into reciprocating motion through the connecting rod mechanism, and the crosshead device drives the plunger to work to complete the working conditions.

Liquid end introduction of ultra high pressure pump :

When the plunger moves back under the drive of the crankshaft, the volume of the inner cavity of the pump head working cylinder gradually increases, the pressure decreases, and a negative pressure is formed. At this time, the drain valve is in a closed state. Under the action of the pressure difference, the inlet valve opens and the liquid enters the working cylinder. When the plunger continues to move to the limit position of the return stroke, the washing liquid process is terminated and the working cylinder is filled with liquid. When the plunger moves in progress, the volume of the working chamber gradually decreases and the pressure increases, so that the inlet valve is closed, the discharge valve is opened, and the liquid is discharged from the discharge channel. When the plunger reaches the end, the volume of the working chamber is the smallest and the pressure is the largest. The plunger continuously reciprocates, and the process of sucking and discharging liquid is continuously alternated, and the high-pressure liquid is continuously discharged from the discharge channel.

Cooling and lubricating system of ultra high pressure pump :

The gear oil pump runs with the rotation of the high-speed shaft, sucking the lubricating oil in the power end box through the cooler, cooling the lubricating oil, and then filtering the lubricating oil through the filter. The filtered low-temperature lubricating oil enters the lubrication parts and lubrication parts of the crankshaft and bearing bushes and other parts that need lubrication.

In the slippery part, the excess lubricating oil is returned to the power end body through the one-way back pressure valve.