Descaling With Powerful High Pressure Technology

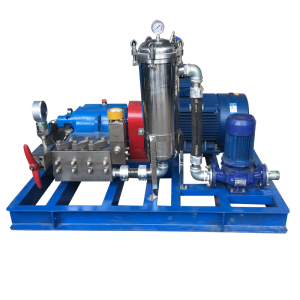

Descaling removes the impurities from iron oxide formed on the surface during the manufacturing process of metal products. In continuous casting and rolling processes, reliable descaling with high-pressure water is possible. The blasting machines work with the individually required pressures. Corrosive and abrasive components of the water place high demands on the pumps used. Phosphorus removal for steel industry is using hydro water jetting method.

The workpiece is cleaned by breaking the scale by the effect of temperature shock and removing the scale with high water pressure. Temperature, evaporation and refractive effects act together in the hydromechanical process on the workpiece and reinforce. Evaporating water acts like small explosions and blows up the scale. Compared to mechanical processes, phosphorus removal with water is much more economical and effective.